Plastic processing at the specialists

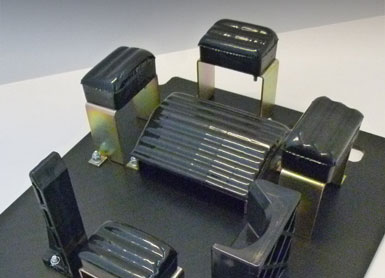

The Viebahn Systemtechnik is the specialist for customer-specific system solutions. We use a variety of methods for plastics processing: Injection molding, foam technology, polyurethane casting technology and the production of composite sheets are standard methods used in our company. We process all common plastics such as soft-PVC, PVC, TPU, TPE, PP, PU, PE, PS, PC-PBT, POM, ABS as well as many in-house blends and compounds.Due to modular construction, our in-house tooling shop is able to produce most tool requirements cost-efficiently within an average of 14 days.

The following properties are applicable on almost all of our processed plastics:

- Integral connections of soft plastics with steel and / or plastic carriers

- 2-component injection molding

- Encapsulation of steel parts, combination with steel-channels

- Shore A plastics are generally available in 45° to 100° hardness

- UV-, oil-, ozone- and weather resistant

- General operation temperature of -40°F to +194°F

- Silicon-free

- Recyclable

- Implementation of specific properties (such as the performance of various fire regulations, swelling, water absorption, electric conductivity, carbon content) in accordance with customer requirements

- Coloration of plastic products selectable within the scope of technical possibilities

- High resilience

- High impact-, upsetting- and tensile strength