Virtual Design - Prototypes - Sample Racks

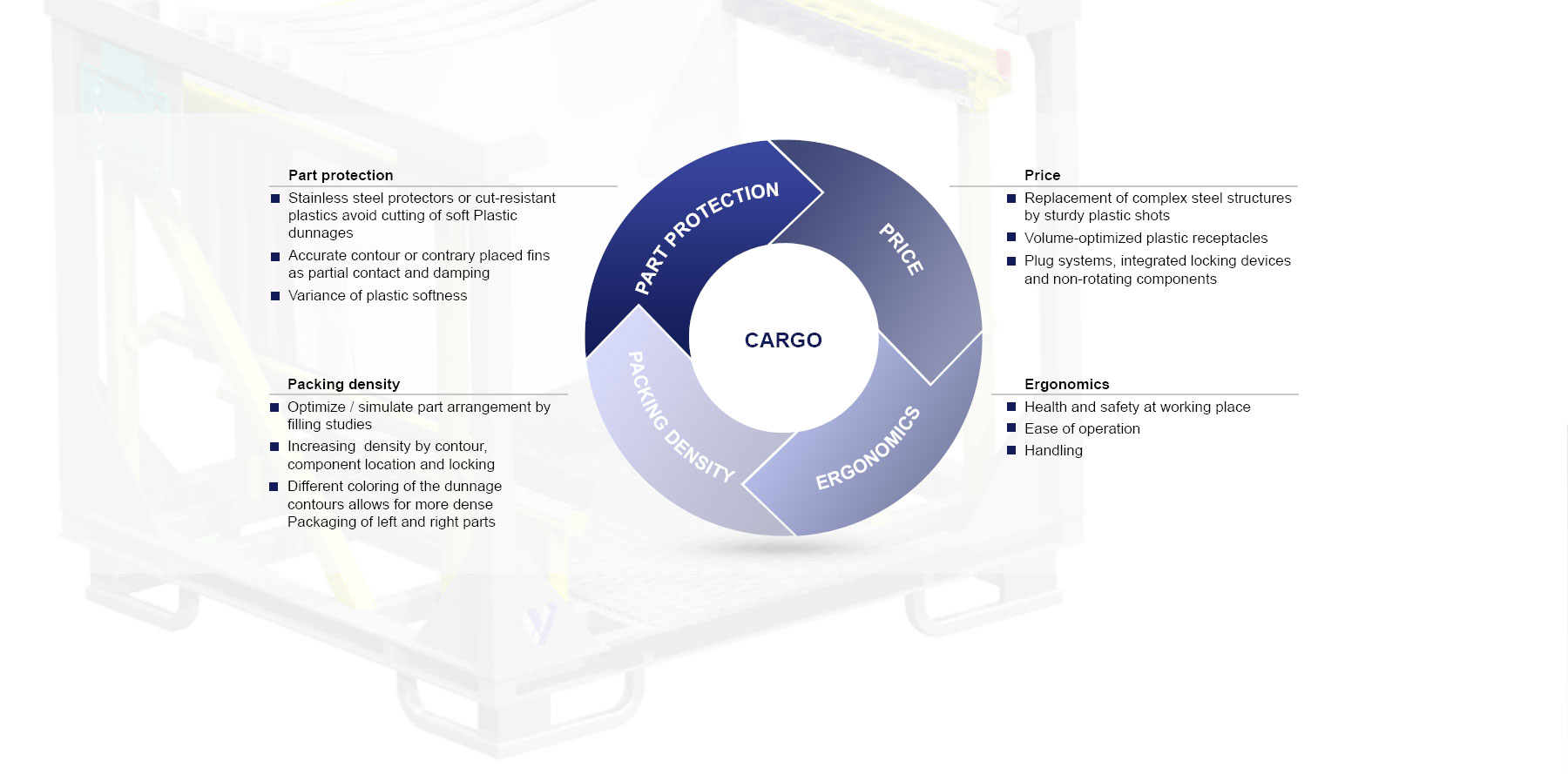

Cargo, the optimum transportation of which should take place individually and impact-protected, requires a special support technology that fixes and separates the respective components, while at the same time protecting the unit from damage. Our employees develop individual solutions and are looking for the optimum balance between ergonomics, packing density, parts protection and price.As a project accompanying service provider, we support you during all processes of rack funding as planning for requirements, product design, construction, material selection and sampling. In addition, we manufacture the necessary production tools and ensure an efficient and cost-effective series production while at the same time observing requirements such as high packing density, parts protection and easy handling.

Our development department has the ability to create rack-design-models from your virtual data and to construct contoured dunnage or separating solutions appropriate to your specific handling requirements. We can finally manufacture prototypes and required sample racks using several plastic-technical manufacturing technologies.

In addition, we are also able to work direct from sample parts to develop concepts. Moreover, we can also transfer this sample part information into a virtual model to create technical simulations and racks.

Significant cost savings due to early involvement of our design and development department we reach for example by:

- Minimal expenditure of steelwork

- Volume-optimized part dunnages

- Easy fitting / assembly of dunnage products into the rack

- Replacement of large / complex steel constructions by using stable plastic solutions

- No protective cover required thanks final assembly after painting of the rack